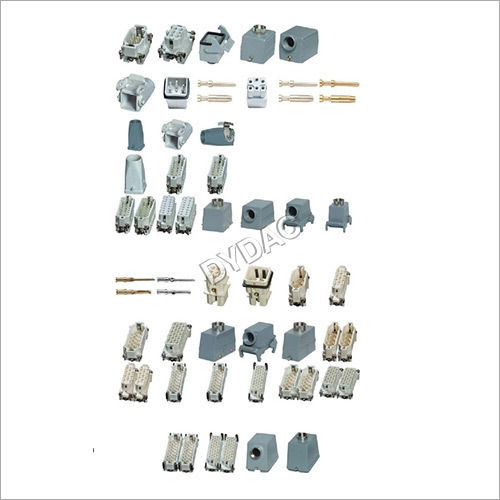

Industrial Heavy Duty Connector

400 INR/Piece

Product Details:

- Material Metal

- Application Industrial

- Color Any Color

- Click to View more

X

Industrial Heavy Duty Connector Price And Quantity

- 1 Piece

- 400 INR/Piece

Industrial Heavy Duty Connector Product Specifications

- Industrial

- Any Color

- Metal

Industrial Heavy Duty Connector Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 2-5 Piece Per Day

- 4-5 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- All India

Product Description

Industrial Heavy Duty Connector is a precision industrial device designed to transmit power data and signal It helps join subsections of circuits together You can easily disconnect the subsections in the future for maintenance purposes The heavyduty connector or HDC is used to connect power inputs peripheral connections or boards Owing to its high build quality and resilience it is preferred by our customers Industrial Heavy Duty Connector has got a userfriendly design and unmatched ergonomics therefore it is easy to work with and maintain

HOT RUNNER SYSTEMS HEAVY DUTY CONNECTOR

Number of Contacts 6 8101624 32 2x16 3248 2 x 24 PE

Electrical Data 16 A 500 V

Working Current 16A

Working Voltage 500V

Rated impulse Voltage 6KV

Pollution Degree 3

Insulation resistance 1010

Flammability VO

Material GLASS FIBRE REINFORCED PLASTIC

Mating cycle 500

Contacts

Material Copper alloy

Surface Hard Silver plated

Contact resistance 1 m

Screw terminal mm2 05 25mm2

Tightening Torque 05 Nm

Stripping Length 70 mm

HoodsHousing

Material DieCast aluminum

Surface Powder Coated

Locking Element Zinc plated Thermoplastic Corrosion resistant stainless steel

Temperature Range 40C 125 0C

Degree of Protection

For Coupled Connector IP65

Number of Contacts 7 8 15 25 40 50 2x25 64 80 2x40 128 2x64 PE

Electrical Data 35 A 250 V

Working Current 10A

Working Voltage 250V

Rated impulse Voltage 4KV

Pollution Degree 3

Insulation resistance 1010

Flammability VO

Material Polymide

Mating cycle 500

Contacts

Material Copper alloy

Surface Hard Silver plated

Contact resistance 3 m

Crimp Termination 014 25mm2

Tightening Torque 05 Nm

Stripping Length 70 mm

HoodsHousing

Material DieCast aluminum

Surface Powder Coated

Locking Element Zinc plated Thermoplastic Corrosion resistant stainless steel

Temperature Range 40 0C 125 0C

Degree of Protection

For Coupled Connector IP65

7 8 IP64

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email