Showroom

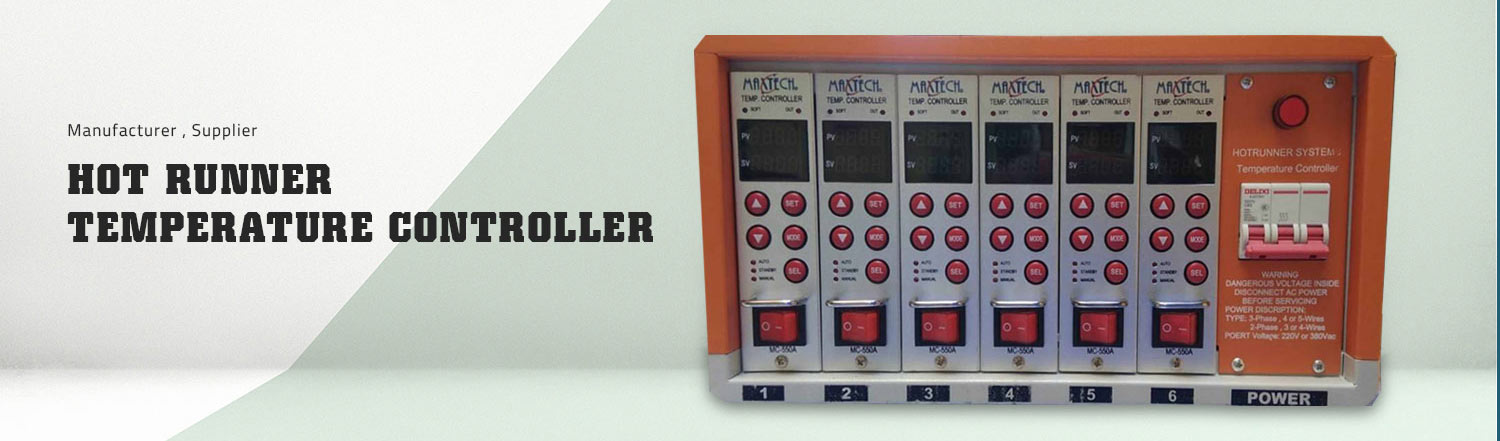

Hot Runner Systems are widely used in plastic processing equipment and machinery. These are heated components used in plastic injection molds. The devices are equipped with high precision solid-state electronic components and units, which make them reliable and functional products.

Thyristor Power Controllers are also known as SCR power controllers. These devices are generally used in industries where power needs to be varied and converted into thermal energy. The controllers are used in industrial furnace construction and in plastic processing.

Temperature PID / Process Controllers are industry-specific instruments designed to control temperature. These devices are used in a plethora of industries including automation, automobile, and various others to control the temperature of the system with the help of a temperature sensor.

Solid State Relays (SSR) are a type of electrical switch that is widely used to turn the electrical system on and off. These devices make use of semiconductor switches and optoelectronics to function. Solid State Relays are suitable for high voltage applications. The relays can withstand heat and voltage fluctuations.

Temperature Control Panels are used to regulate the temperature of a process efficiently. These panels are the brain of heating systems. The control panels come with a range of control options and accessories. These are robust devices with the capability of withstanding voltage fluctuations and heat.

Thyristor Power Controllers are used in industrial applications to control power or voltage supplied to a load. These are used widely in processes where power needs to be varied in a controlled and efficient manner. The process controllers are generally used in industrial furnaces and in plastic processing machines.

Industrial Heaters are used extensively in a range of processes where the temperature of an object or process needs to be increased. These heaters are equipped with the ruggedized heating element that helps in controlled heating of the object under treatment.

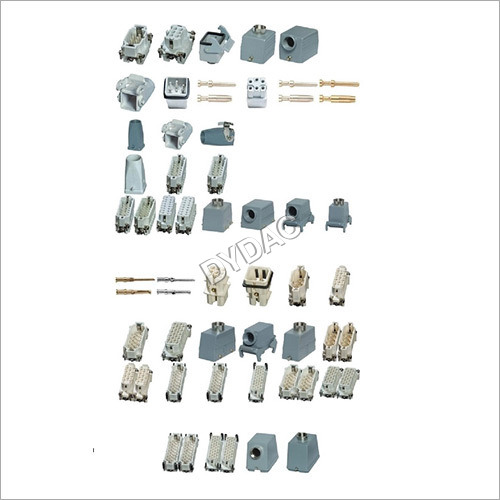

Heavy Duty Connectors are used to join subsections of circuits together. These connectors are resilient and robust, therefore, they can withstand heavy loads, voltage fluctuations, and unfavorable conditions. Heavy Duty Connectors have got an ergonomic design and user-friendly operations.